Ultrafine air bubbles, also known as microbubbles or nanobubbles, are tiny bubbles with diameters typically ranging from a few micrometers to less than 100 nanometers. Their small size imparts unique properties that make them highly effective in a variety of applications.

Generation of Ultrafine Air Bubbles

Several methods exist for generating ultrafine air bubbles, including:

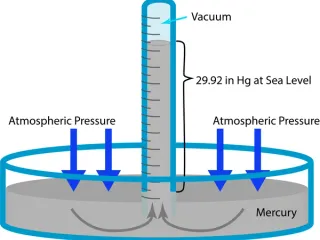

- Dissolved Air Flotation (DAF): This is a common method where air is dissolved under pressure into water, then the pressure is released, causing the dissolved air to form tiny bubbles.

- Venturi systems: These systems use a converging-diverging nozzle to create a vacuum, drawing air into a liquid stream and generating small bubbles.

- Ultrasonic cavitation: High-frequency sound waves create cavitation bubbles which subsequently collapse into smaller bubbles.

- Electrochemical methods: These methods utilize electrolysis to generate bubbles directly from the liquid.

Applications of Ultrafine Air Bubbles

The unique characteristics of ultrafine air bubbles make them valuable in various industries:

- Wastewater Treatment: In Dissolved Air Flotation (DAF) systems, ultrafine bubbles efficiently attach to suspended solids, facilitating their separation and removal.

- Aquaculture: Microbubbles increase oxygen transfer in aquaculture systems, improving water quality and fish health. They also enhance nutrient distribution.

- Chemical Processing: Ultrafine bubbles can improve mixing, enhance reactions, and facilitate the separation of components in chemical processes.

- Medical Applications: Research is ongoing into the use of ultrafine bubbles in drug delivery and imaging.

Benefits of Using Ultrafine Air Bubbles

The advantages of utilizing ultrafine air bubbles include:

- Increased surface area: The small size results in a significantly larger total surface area compared to larger bubbles, enhancing mass transfer.

- Longer residence time: Ultrafine bubbles remain suspended in the liquid for longer periods, improving efficiency.

- Improved mixing and dispersion: They facilitate more efficient mixing and better dispersion of liquids and solids.

Future Trends

Research and development in ultrafine air bubble technology continue to explore new applications and more efficient generation methods. Further advancements are expected in areas like advanced materials, energy efficiency, and process optimization.

For more in-depth information, consider exploring research papers from leading academic databases such as Web of Science and Scopus.